Mold Trial Production Operations Manual 1. Realization of all related information about the form: Better check the mold design layout and material properties, to study carefully. 2. Check all mechanical movements before loading the mold onto the machine. " Check if scratches, components are missing or the situation worsens or not ... etc. Check molding direction, sliding plate movement is correct or not ... water channel and vent connection leaking or not. 3. When you make sure all shapes are correct, choose the right mold fungus test Machine or mass production machine, before the election, pay attention to the the following points: on. the max. Shot size of the molding machine is enough or not for the operation of this mold. b. In between, the size of the bar is sufficient to set this shape or not. c. The size of the lifting movement of the machine is sufficient for the operation of this form or not. d. The rest of tool or series production tools or accessories are ready or not. All the above points are all right, load on the form. After the mold is loaded, carefully check the mechanical movement of all molds (eg Close mold, slide, ejector pin ... etc) is correct or not. The next step is to pay attention to the movement of the shape spots at this moment, Operator should reduce, test / see and hear the closing pressure whether there are any restless movements or strange noises or not Machine manual type and low speed dormouse motion condition. 4. mold temperature: Depending on the material condition and tool size, you select the appropriate tool Tool temperature controller for heating up the required tool temperature. Waiting temperature has expired, must be checked again after all the above movements. Because the mold steel could expand with heat and cause mildew Location. Therefore, all movements must be observed so as not to cause any dragged damage or mold exciting situation. 5. Suggest setting mold parameters once with only one condition to analyze the single parameter adjustment, which affects the part result variation in detail. 6. Depending on the material difference, bake the material with the appropriate temperature. 7. Try to use the same material for the mold trial and future mass production. 8. Do not use the second hand material, if there is a color requirement, try it Try the material color together with the mold trial. 9. Before the molding test, the positive locking pressure must be set well and try to see little Times of movement to see if the shape spot pressure is uneven or not, in To prevent the parts from flashing or deforming. Before you take the first picture, check again the following: on. The material addition process is too long or too short. b. Pressure is too high or too low c. Material fill speed is too fast or too slow d. Cycle time is too long or too short. To avoid the parts, short shot, breakage, deformed, lightning or mildew damage. If the cycle time is too short, the ejector pin will break the parts or crush the parts. Therefore, you must weigh the situation carefully and prepare the necessary solution, only to avoid a serious and expensive loss.

-

Design / Konstruktion für SpritzgusswekzeugDesign / Konstruktion für Spritzgusswekzeug Der Formenbau für den Spritzgusshersteller ...

Design / Konstruktion für SpritzgusswekzeugDesign / Konstruktion für Spritzgusswekzeug Der Formenbau für den Spritzgusshersteller ...Mögen Sie ?0

Weiterlesen -

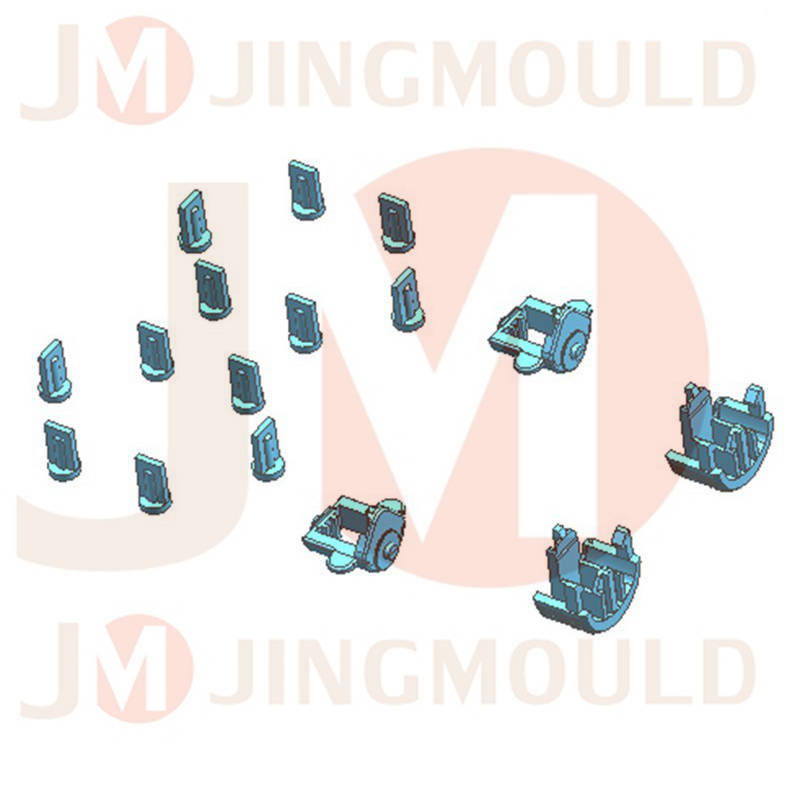

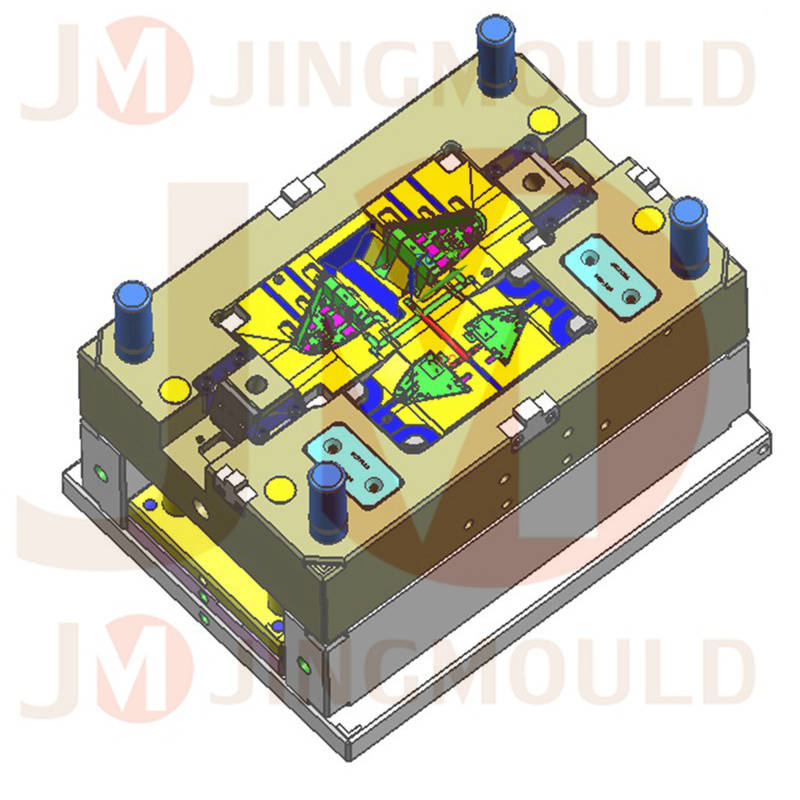

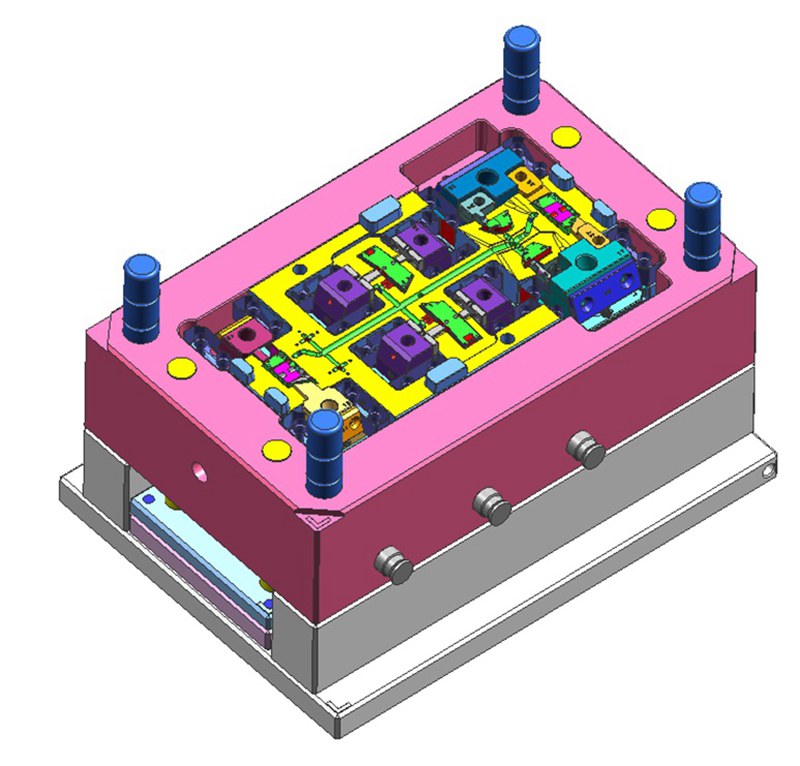

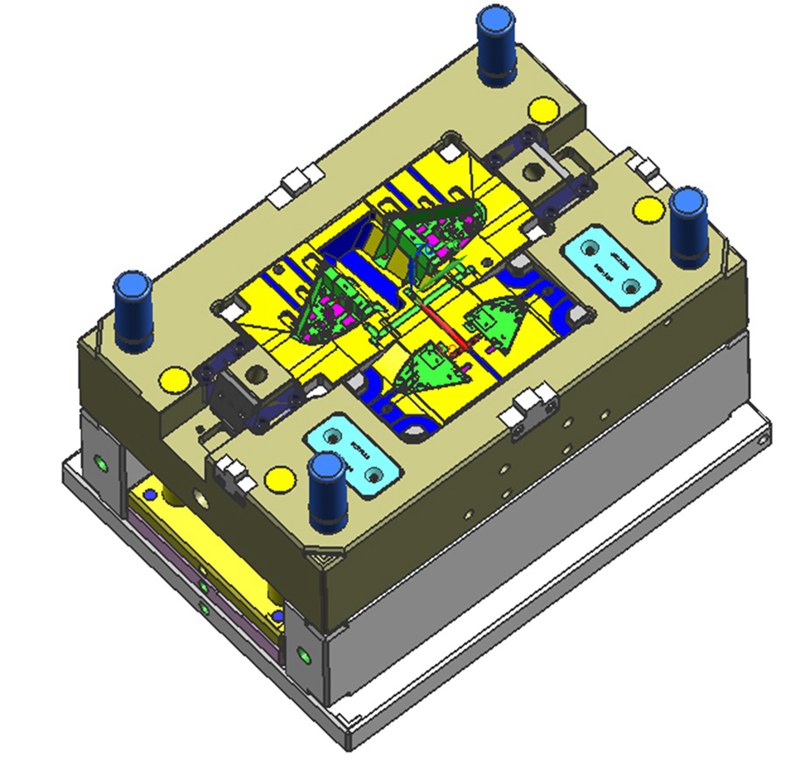

Mold design for injection moldingMold design for injection molding manufacturer Jingmould offers a wide range design of mold, tooli...

Mold design for injection moldingMold design for injection molding manufacturer Jingmould offers a wide range design of mold, tooli...Mögen Sie ?0

Weiterlesen -

2022 Preferred Quality Supplier Award from ABB ChinaIt is a great honor for us to receive this special award. Thanks to the hard work of Jingmould te...

2022 Preferred Quality Supplier Award from ABB ChinaIt is a great honor for us to receive this special award. Thanks to the hard work of Jingmould te...Mögen Sie ?0

Weiterlesen -

How CNC Machining Works: An OverviewHow Does CNC Machining Work? CNC machining is a subtractive manufacturing process that ...

How CNC Machining Works: An OverviewHow Does CNC Machining Work? CNC machining is a subtractive manufacturing process that ...Mögen Sie ?0

Weiterlesen -

Präzisions Pulvermetall Formteile aus ChinaIndividuelle Pulver- (Sinter-) metallteile nach Kundenzeichnung vom chinesischen Marktführer ...

Präzisions Pulvermetall Formteile aus ChinaIndividuelle Pulver- (Sinter-) metallteile nach Kundenzeichnung vom chinesischen Marktführer ...Mögen Sie ?0

Weiterlesen -

CNC Machining SERVICECNC Machining Jingmould offers high-precision CNC machining services with quick turnarounds. With...

CNC Machining SERVICECNC Machining Jingmould offers high-precision CNC machining services with quick turnarounds. With...Mögen Sie ?0

Weiterlesen